D671X Pneumatic Wafer Butterfly Valve Series

manufacturer: Kaiweixi Valve Group Co., Ltd

Eml: Carrie@kaiweixi.com

Tel: +86 (577) 67038872

Mob: +86 189 6779 6392(WeChat Same Account)

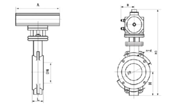

product drawing

D671X Pneumatic Wafer Butterfly Valve Series

Overview

The D671X Pneumatic Wafer Butterfly Valve is an automated valve designed for the rapid on/off operation or regulation of pipeline fluid flow. Utilizing compressed air as the power source, it employs a pneumatic actuator to drive a 90-degree rotation of the disc. The valve features a wafer-style connection, where it is directly clamped between two pipeline flanges via bolts on both sides of its body, resulting in a compact installation with minimal spatial footprint. The pneumatic actuator converts air pressure into rotary torque, which precisely drives the valve stem and the connected disc within the valve body. The disc's sealing surface is integrally lined with an elastic material such as rubber, forming a soft seal through an interference fit with the valve body. During the opening and closing process, the disc quickly disengages from and re-engages with the valve seat, enabling highly efficient fluid control. Characterized by fast response, ease of operation, and a high degree of automation, the D671X Pneumatic Wafer Butterfly Valve is widely used in water supply and drainage, fire protection, HVAC systems, and various industrial automation control applications.

Features

1、Pneumatic Quick Response:Equipped with high-performance single/double-acting pneumatic actuators,enabling rapid opening and closing (completed within 0.5–3 seconds), responsive operation, and suitability for frequent switching. Ideal for automated control systems.

2、Wafer-Type Compact Design:The valve body adopts a wafer-type structure,featuring short installation length, small size, and lightweight construction. Saves pipeline installation space and is especially suitable for densely arranged pipelines or space-constrained applications.

3、High-Performance Soft Seal:The disc sealing ring is fully overlaid with high-quality EPDM, NBR, or FKM rubber, offering excellent sealing performance to achieve zero leakage (sealing class up to Class VI) and compatibility with various media.

4、Reliable Bidirectional Sealing:The design ensures reliable sealing under both forward and reverse pressure, independent of medium flow direction.

5、Low Flow Resistance, Energy-Efficient:When fully open, the disc is parallel to the flow direction, providing a smooth flow path with minimal fluid resistance. Effectively reduces system pressure loss and saves energy.

6、Corrosion-Resistant, Long Service Life:Valve body materials include ductile iron, carbon steel, or stainless steel, with surface anticorrosion treatments such as epoxy resin coating. Sealing materials resist chemical corrosion, extending valve service life.

7、Smart Control Compatibility:Can be equipped with accessories such as solenoid valves, limit switches, positioners, and filter regulators for easy integration into PLC, DCS, and other automated control systems, enabling remote control and precise adjustment.

8、Easy and Economical Maintenance:Modular design with a simple structure allows easy disassembly. Key sealing components can be replaced quickly, supporting online maintenance to reduce downtime and maintenance costs.

Dimensions & constructral diagram

D671X Pneumatic Wafer Butterfly Valve Series constructral diagram(pic1)

The main technical parameters

| Name | Material |

|---|---|

| Pneumatic Actuator | Aluminum Alloy (Cylinder Body) + Carbon Steel (Accessories) |

| Valve Stem | Stainless Steel (316, Corrosion-Resistant) |

| Butterfly Disc | Carbon Steel (Base) + PTFE (Liner) |

| Seals | PTFE or Fluororubber |

| Valve Seat | PTFE |

| Bolts / Nuts | Stainless Steel (316, Corrosion-Resistant) |

| Valve Body | Carbon Steel (Base) + PTFE (Liner) |

Standard

| Item | Specification | Unit |

|---|---|---|

| Nominal Pressure (PN) | 1.6 | PN |

| Strength Test Pressure | 2.4 | MPa |

| Seal Test Pressure | 1.76 | - |

| Operating Temperature Range | ≤150 | ℃ |

The main external and connection dimensions

| DN | Principal External Dimensions | 0.6MPa | 1.0MPa | 1.6MPa | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| L | H | HO | A | B | D0 | n-d | D0 | n-d | D0 | n-d | |

| 50 | 43 | 63 | 315 | 180 | 65 | 110 | 4-14 | 125 | 4-18 | 125 | 4-18 |

| 65 | 46 | 70 | 330 | 180 | 65 | 130 | 4-14 | 145 | 4-18 | 145 | 4-18 |

| 80 | 46 | 83 | 390 | 245 | 72 | 150 | 4-18 | 160 | 8-18 | 160 | 8-18 |

| 100 | 52 | 105 | 431 | 240 | 72 | 170 | 4-18 | 180 | 8-18 | 180 | 8-18 |

| 125 | 56 | 115 | 455 | 240 | 72 | 200 | 8-18 | 210 | 8-18 | 210 | 8-18 |

| 150 | 56 | 137 | 626 | 350 | 93 | 225 | 8-18 | 240 | 8-22 | 240 | 8-22 |

| 200 | 60 | 164 | 720 | 350 | 93 | 280 | 8-18 | 295 | 8-22 | 295 | 12-22 |

| 250 | 68 | 206 | 805 | 500 | 355 | 335 | 12-18 | 350 | 12-22 | 355 | 12-26 |

| 300 | 78 | 230 | 860 | 600 | 350 | 395 | 12-22 | 400 | 12-22 | 410 | 12-26 |

| 350 | 78 | 248 | 883 | 600 | 350 | 445 | 12-22 | 460 | 16-22 | 470 | 16-26 |

| 400 | 102 | 289 | 972 | 600 | 350 | 495 | 16-22 | 515 | 16-26 | 525 | 16-30 |

| 450 | 114 | 320 | 1043 | 750 | 380 | 550 | 16-22 | 565 | 20-26 | 585 | 20-30 |

| 500 | 127 | 343 | 1098 | 750 | 380 | 600 | 20-22 | 620 | 20-26 | 650 | 20-33 |

| 600 | 154 | 413 | 1236 | 750 | 380 | 705 | 20-26 | 725 | 20-30 | 770 | 20-36 |

| 700 | 165 | 478 | 1431 | 750 | 380 | 810 | 24-26 | 840 | 24-30 | 840 | 24-36 |

| 800 | 190 | 525 | 1488 | 750 | 380 | 920 | 24-30 | 950 | 24-33 | 950 | 24-39 |

| 900 | 203 | 620 | 1615 | 1250 | 380 | 1020 | 24-30 | 1050 | 28-33 | 1050 | 28-39 |

| 1000 | 216 | 725 | 1765 | 1500 | 580 | 1120 | 28-30 | 1160 | 28-36 | 1170 | 28-42 |

| 1200 | 254 | 780 | 1976 | 1500 | 580 | 1340 | 32-33 | 1380 | 32-39 | 1390 | 32-48 |